Phone Numbers -

Email ID -

Physical Address -

Shop No- 6B, Ground Floor, Sindhi Ln, opposite Municipal School, Charni Road East, Cawasji Patel Tank, Girgaon, Mumbai, Maharashtra 400004

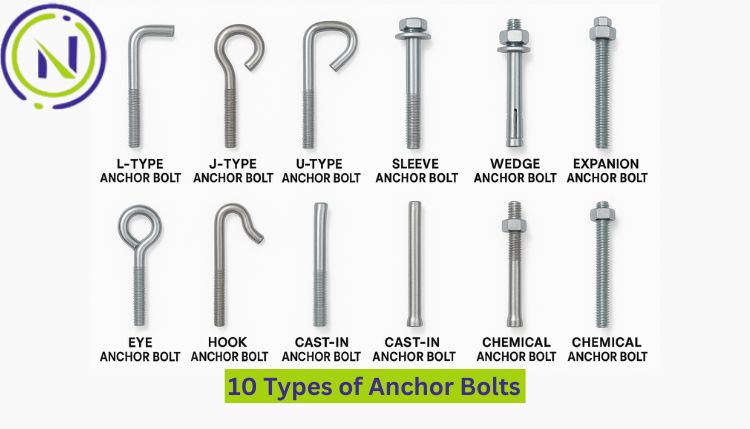

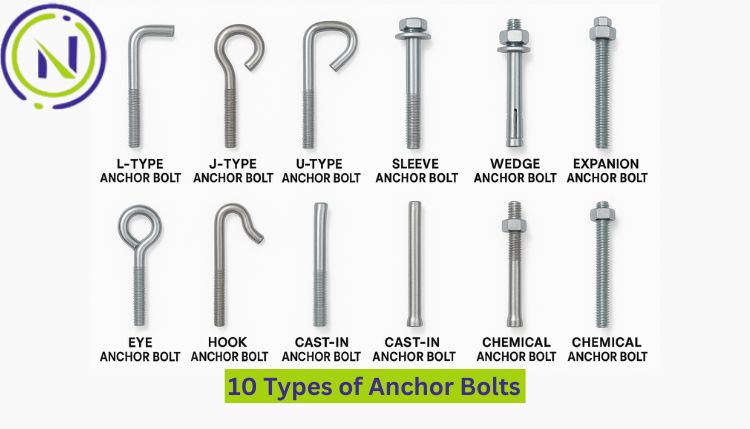

Anchor bolts are essential fasteners used to attach structures or equipment to concrete. They provide secure and stable support in applications ranging from buildings and bridges to machinery and pipelines. With varying designs, shapes, and materials, different types of anchor bolts serve different structural and industrial purposes.

At Neelkamal Fasteners LLP, we manufacture and supply a wide variety of high-quality anchor bolts used across construction, power plants, railways, petrochemicals, and infrastructure projects. In this guide, we’ll cover the 10 most common types of anchor bolts, their characteristics, and their typical applications.

L-shaped anchor bolts are bent at a 90-degree angle at one end. This bend helps the bolt resist pull-out from the concrete once set.

Similar to the L-type, J-bolts are bent into a “J” shape, providing better grip within the concrete. The curve prevents the bolt from loosening under load.

U-bolts are shaped like the letter “U” with two threaded legs. They are used to attach round objects like pipes or tubing to concrete or steel.

Sleeve anchors consist of a threaded bolt inside a cylindrical sleeve. When tightened, the sleeve expands to anchor the bolt in place.

A wedge anchor expands and wedges itself into the drilled hole in concrete when the bolt is tightened, offering high pull-out resistance.

Expansion bolts work on the principle of mechanical expansion. Tightening the nut pulls a cone into the sleeve, expanding it against the concrete wall.

Eye bolts have a looped head and are used as lifting or tie-down points in concrete. They can be cast-in or post-installed.

Hook bolts feature a curved or open-ended hook on one side. These are commonly embedded into concrete to hang heavy objects or structural components.

Cast-in-place anchor bolts are placed in the concrete formwork before pouring. Once the concrete cures, the bolt becomes a permanent part of the foundation.

Chemical anchors involve placing a resin (epoxy or polyester) into a drilled hole, followed by insertion of the anchor bolt. The resin hardens to create a high-strength bond.

At Neelkamal Fasteners LLP, we ensure each anchor bolt meets stringent industry standards with:

We serve clients across construction, infrastructure, oil & gas, transmission line towers, and more.

Understanding the 10 types of anchor bolts allows engineers, fabricators, and contractors to select the right fastening solution for their application. Whether it’s an L-type for foundation bolts or a chemical anchor for seismic zones, each type offers unique benefits.

Trust Neelkamal Fasteners LLP for reliable, precision-manufactured anchor bolts that ensure strength, stability, and performance in your most demanding projects.